Tekni-Plex Healthcare – medical grade tubing

Tekni-Plex Healthcare is an expert in manufacturing medical grade PVC tubing (formerly Natvar) in a wide variety of configurations, grades and durometers. Our solutions also extend into other polymers and coextrusions commonly used in single-use medical device applications. These include polyolefins, such as polypropylene and polyethylene, thermoplastic polyurethanes (TPUs) and ethylene-vinyl acetate (EVA). Our coextrusions of polyolefin lined, PVC tubes are world renowned for medical gas and fluid transmission applications.

Single Lumen Tubing

Our medical grade PVC tubing offers exceptional clarity and flexibility for single-use devices.

Our material selection includes PVC Compounds, Cellene TPE Compounds, as well as other materials such as polyolefins, polycarbonates, silicone, and other high performance materials. Our proven extrusion technology and advanced equipment are able to extrude to very tight tolerances and specifications.

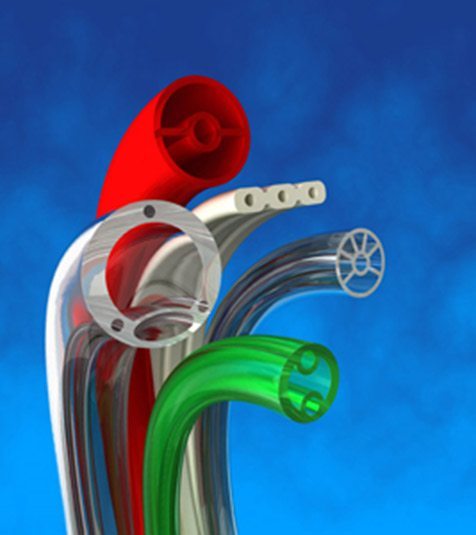

Multi-Lumen Tubing

Our medical grade multi-lumen tubes are available for applications that require multiple flow or working channels in a single tube.

Our material selection includes PVC Compounds, Cellene TPE Compounds, as well as other materials such as polyolefins, polycarbonates, silicone, and other high performance materials. Our proven extrusion technology and equipment are able to extrude to tight tolerances and specifications. We customize the tubing to meet our customer specifications, including diameter, thickness, material, lumen geometry and rating.

Multi-Layer Tubing

Our multi-layer medical tubing includes several layers of various materials to optimize performance in the specific application.

Our multi-layer tubing is available in a variety of material constructions and can utilize various materials including PVC Compounds, Cellene TPE Compounds, polyurethane, polypropylene, EVOH, and other high performance materials. Our multilayer technology choices include tubing configurations with up to 5 layers. Most of the standard configurations include a bonding or tie layer to mitigate the risk of any delamination during tensile shock. Several of these unique product designs are patented. In addition, our extrusion process has 100% inline inspection of the tubing ID to ensure the fluid path is occlusion free.

Medical Pump Tubing

Our medical pump tubing is available in a range of materials from FlexChem SR, FlexChem, ElastiChem, Cellene TPE, silicone, as well as other high performance materials to meet the stringent demands of the application.

Wire Embedded Tubing

Power-path™ PVC medical tubing with embedded wires provides data and fluid transmission simultaneously in a single tube.

Bubble and Transition Tubing

This tubing type eliminates the need for plastic connector fittings.

Coiled Tubing

Coiled tubing provides unparalleled elongation, while maintaining consistent fluid or gas flow channels.