Sustainable Products

At Tekni-Plex, sustainability is at the heart of Product Innovation. We embrace the design principles supported by the Ellen MacArthur Foundation and develop products that are recyclable in common waste streams and/or contain recycled content, in order to reduce the footprint on the earth we share.

Closure Liners

|

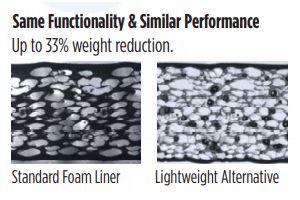

Reduce: Lightweight Polyethylene (PE) LinersFor applications where the proven performance characteristics of PE are required, Tekni-Plex offers a lightweight alternative that weighs up to 33% less than the traditional PE/LDPE coextruded foam liner, providing the same characteristics with a more sustainable footprint. With this addition to the portfolio, Tekni-Plex takes a unique position in the market by offering the largest range of foamed liner densities in single- and multilayer structures. |

|

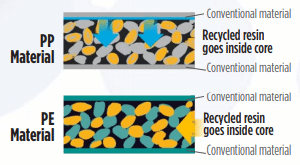

Reuse: Recycled content in core layersFor suitable applications, we offer liner products with a core layer that includes post-industrial recycled content made from the skeleton remaining after a PE or PP sheet is punched by our customers. Our customers then return the punched PE or PP skeleton to Tekni-Plex to be pelletized and reused in other products. |

|

Recycle: Polypropylene (PP) LinersSubstituting a PP closure liner for a PE closure liner makes the closure and the liner (together) easier for recycling into a single recycling stream. Tekni-Plex offers a PP closure liner that provides the same performance characteristics as a PE liner, but has the added benefit of making the closure fully recyclable in a single stream. |

Post-Consumer Mechanically Recycled Resin (PCR)

Tekni-Plex offers LDPE dispensing tubes made with 100% PCR and HDPE/PP dispensing tubes made with 80% PCR. A key requirement for produucts manufactured using PCR is that they have the same performance characteristics of products manufactured using conventional resin. The PCR used to manufacture our dispensing tubes offers similar processability as conventional resin and produces products with similar performance characteristics.

TekniMD® and Tekniflex® PX: A Sustainable and Recyclable Alternative to PVC and PETG

Packaging plays a critical role in ensuring the integrity of life-saving medical devices and pharmaceutical products. Until recently, this type of packaging was not easy to recycle.

Tekni-Plex’s TekniMD® PX and Tekniflex® PX are high-performance, thermoformable, proprietary copolyester films that are suitable for #1 PET stream recycling, alongside soft drink bottles. They offer an ideal alternative to PVC and PETG structures. Tekniflex® PX film and TekniMD® PX have been evaluated by an independent third-party laboratory to determine its suitability for recycling in the #1 polyethylene terephthalate (PET) waste stream.

First Pharmaceutical Blisters Containing Circular Polymers

Tekni-Plex has been a long-time provider of high quality, reliable products to the pharmaceutical blister market, offering a variety of barrier film structures to protect sensitive drugs over their shelf life. Historically, PVC has been the material of choice for such structures, often complemented with barrier layers such as PVDC or PCTFE (Aclar®).

Tekni-Plex was one of the first suppliers to offer a complementary series of polyolefin blister films, Tekniflex® COC and Tekniflex® ECO, demonstrating high recyclability scores in the PP waste stream.

These substrates provide the same superior barrier to moisture and oxygen and can easily be used in place of other substrates on existing thermoforming equipment .

Tekniflex® COC and Tekniflex® ECO are formulated with PP skin layers. Tekni-Plex has secured access to circular polymers and introduced alternative versions of Tekniflex® COC and Tekniflex® ECO now containing chemically recycled PP resin.

Through the chemical recycling process, Tekniflex® COC and Tekniflex® ECO can be manufactured with up to 30% chemically recycled material.

Recyclable Paper Materials For Healthcare Applications

Tekni-Plex healthcare packaging produces multiple recyclable options for use in medical device packaging. Paper is a commonly used packaging material for multiple product applications. Both coated and uncoated paper are considered recoverable within the waste stream.

The coatings use ingredients that include PVA polymers, EVA/LDPE components, tackifiers, waxes, and/or polychloroprene ingredients to achieve the appropriate end-use performance. The coatings represent a minority of the total weight of the coated paper structure such that 80% or more of the product is recoverable as paper fibers.

Whether these products can be recycled into paper pulp is largely a function of the types of available collection systems, the repulping equipment capability, and the desired end product of the recycler. The coatings on the products can be physically separated from the pulp by screening or with the use of a centrifugal separator.

Food Packaging

Keeping food safely and securely packaged is a critical part of our food supply chain, and Dolco Packaging’s polystyrene (PS) foamed egg cartons, poultry and meat processor trays, and other products are an essential part of the solution.

Each year Dolco uses about 10 million pounds of post-industrial recycled PS, all of which was previously sent to a landfill. Dolco also regrinds and reuses almost all of the PS scrap generated in production. In addition, all Dolco manufacturing facilities accept PS egg cartons for recycling and a few locations also accept other types of PS products.

For example, Dolco’s Wenatchee, Washington, manufacturing location has partnered with chemical recycler Agilyx to expand recovery and recycling of not just the PS packaging manufactured and collected by Dolco, but also other PS consumer packaging collected from the local community. Agilyx uses its proprietary recycling technology to create new, next-generation PS, which can be used by Dolco, with the goal of increasing global plastic recovery.

In addition, Dolco’s Decatur, Indiana, manufacturing location partners with Walmart and its recycling partner to collect and reprocess used clothes hangers from Walmart stores. This post-consumer recycled plastic makes up 5% of the egg carton composition shipped to Walmart stores from the Decatur manufacturing facility.